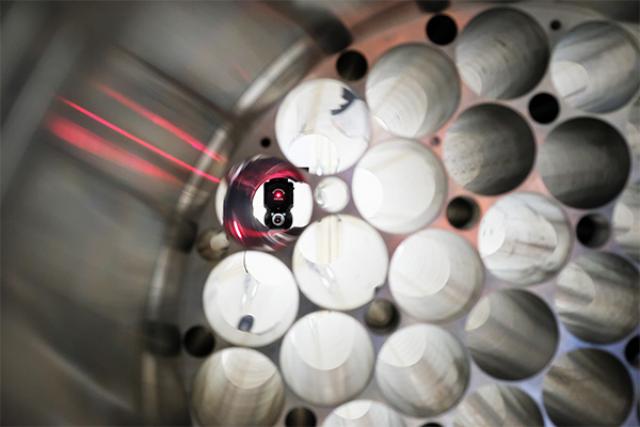

The core of Jules Horowitz Reactor, under pressure nuclear equipment

Key figures

Of projects carried out by CNIM Systèmes Industriels

Total weight

Component assembly precision

High-performance fabrication for a complex industrial project

The Jules Horowitz Reactor (JHR) is a high-tech research reactor intended for use in safety qualification processes for irradiated materials and nuclear fuels. The JHR will be an international R&D facility with a mission to enhance nuclear power plant safety and reliability.

It is the result of an international collaborative effort coordinated by the Atomic Energy Commission (CEA). In 2007, a consortium formed by EDF, Areva and an array of Belgian, Czech, Spanish, Finnish, Indian, Israeli, Swedish and British research institutions appointed TechnicAtome (TA.) as contracting authority for the reactor construction project.

In 2015, TA. awarded CNIM Systèmes Industriels the contract to manufacture the reactor’s core, known as the reactor block.

This project required exceptional industrial capabilities. CNIM Systèmes Industriels met all the requirements: precision machining of large components; expertise in nuclear materials and components; outstanding welding know-how, etc.

Operational excellence for nuclear safety

Significant industrialization capabilities

CNIM conducted a program of preliminary studies to verify manufacturability and address the requirements stipulated by TA.

- CAD machining program simulations

- Full-scale models

- Test bed for the electron beam-welded joints on the 6061 T6 alloy reactor tank.

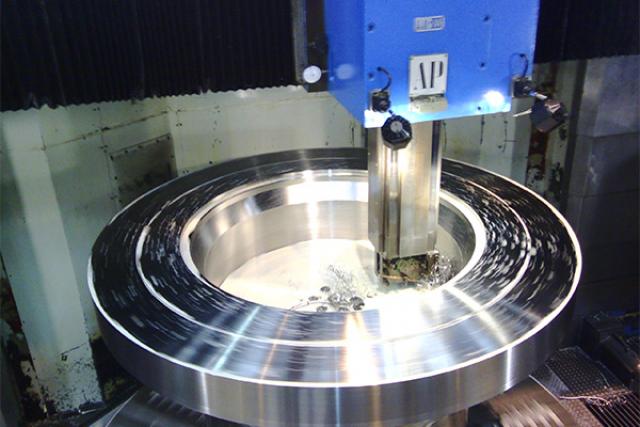

Complex and large component machining

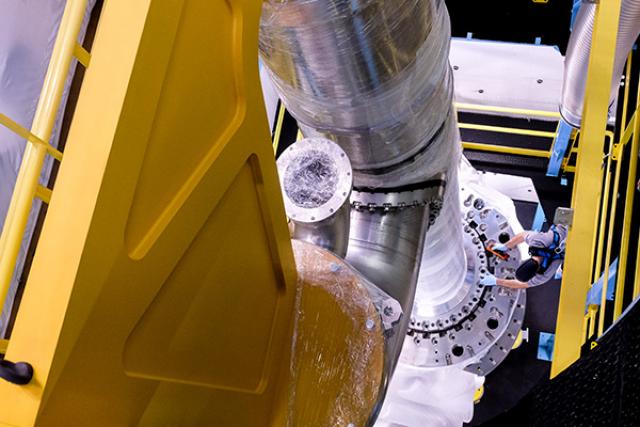

The exceptional dimensions of the reactor block (H 9 m x W 2 m, weighing of 20 tons) required custom industrial facilities.

CNIM possessed the necessary state-of-the-art industrial equipment, specially designed for precision machining fabricated assemblies and large or complex components.

High accuracy assembly

The high degree of precision with which CNIM machined components would enable the reactor block to be assembled at the customer’s site to the tightest of tolerances.

- TechnicAtom conducted alignment tests that demonstrated a positioning accuracy to within 0.1 mm.

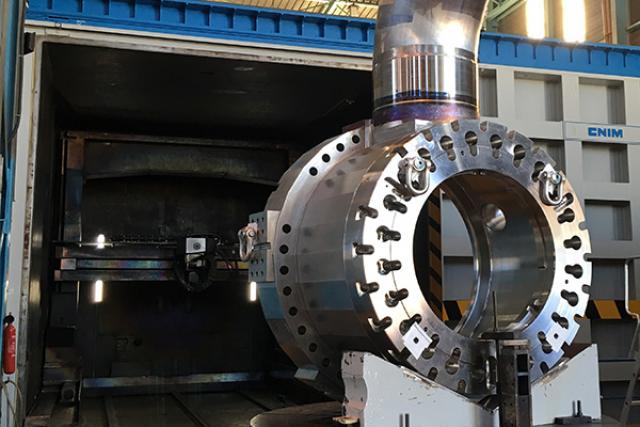

Unique expertise in electron beam welding

The reactor block is a complex component that has benefited from CNIM’s multi-material expertise. Unlike most reactor cores, traditionally designed using stainless steel, the JHR core is made of aluminum. Welding aluminum components can release gases and form porosities, potentially weakening the structure. Consequently, TA. specified the use of electron beam welding techniques to avoid any risk of cracking.

CNIM owns a patent in this area and is acknowledged to be an authority.

Compliance with safety standards applicable to nuclear pressure equipment

We ensure the compliance with the technical requirements concerning nuclear pressure equipment, as welding standards and the European Directive on nuclear pressure equipment.

- Traceability according to AQ84

- earthquake-resistant design

- Clean working conditions for hydrostatic testing and assembly

Validation of performances by qualification tests

- Helium leak testing

- Validation of manufacturing process (electron beam welding of stainless steel and aluminum components according to the RCCMX),

- Mock-up manufacturing